Add to Cart

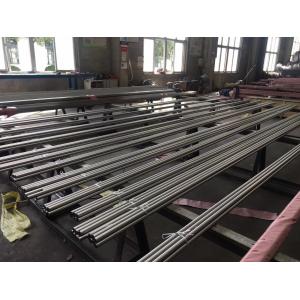

DIN X46Cr13 EN 1.4034 DIN X39Cr13 EN 1.4031 Stainless Steel Round Bars

Steel grades, chemical composition %

| Grade | C | Si | Mn | P | S | Cr | Ni |

| X46Cr13 - 1.4034 | 0.43~0.50 | 1.00 | 1.00 | 0.040 | 0.030 | 12.50~14.50 | 0.60 max |

| X39Cr13 - 1.4031 | 0.36~0.42 | 1.00 | 1.00 | 0.040 | 0.030 | 12.50~14.50 | 0.60 max |

| X40Cr14 - 1.2083 | 0.36~0.42 | 1.00 | 1.00 | 0.030 | 0.030 | 12.50~14.50 | |

| X46CrS13 - 1.4035 | 0.43~0.50 | 1.00 | 2.00 | 0.040 | 0.15~0.35 | 12.50~14.50 | |

| 40Ch13 - 40Х13 | 0.36~0.45 | 0.80 | 0.80 | 0.030 | 0.025 | 12.00~14.00 | 0.60 |

Specifications

Tool, wear resistant stainless steel with martensitic structure for thermal improvement.

After heat treatment has high hardness of about 52-54 HRC.It is used in the production of cutting tools,

bearings, pipes and protective sleeves, springs, screws, pistons, kitchen knives, industrial knives for machines,

carburetor needles, surgical and measuring instruments.Used in the chemical, petrochemical, food,

and machine industries, has sufficient corrosion resistance in the environment containing some organic acids,

salts, water, alcohols, and liquid fuels.

Available forms

Drawn wires / bars, peeled bars, hot-rolled bars X46Cr13, 1.4034 , X39Cr13 , 1.4031 , X40Cr14 , 1.2083 , 40Ch13

For Details, please Contact

WUXI GUANGLU Special Steel Co., Ltd.

Stainless martensitic • precipitation hardening steel • stainless ferritic — Our answer to your needs

Tel: +86 510 81812873

Email: export@guanglusteel.com